As an engine valve manufacturer, we provide high quality engine valves to customers in a variety of fields, including major automobile manufacturers, agricultural machinery manufacturers, and construction machinery manufacturers in Japan.

Division Outline

| Applications | 4-Wheeled vehicles, Motorcycles, Outboard motors, General-purpose engines |

|---|---|

| Arbor diameters | Stem diameter 4mm to 18.0mm Umbrella outer diameter:12.0mm to 70.0mm |

| Materials | SUH3 SUH35 SUH11 SUS304 Inconel Titanium SCM435 |

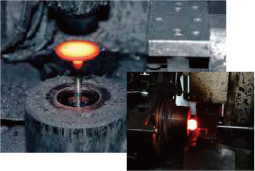

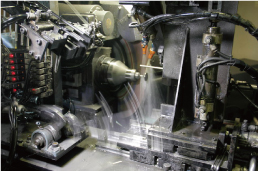

| Process Types | Shear cutting, Friction welding, Upset forging, Extrusion forging, Hheat treatment (quenching and tempering), Straightening, Face/Top filling (PPW TIG), Second forging, Turning and Grinding, Surface treatment |

| Facilities/ Equipment |

Mold manufacturing equipment, Upsetters, Screw presses, Heat treatment furnaces, Shot blasting machines, Straightening machines, Valve finishing machines |

Process

Cutting / ChamferingUpset forgingHeat treatmentMachining